Product

Product features:1. The machine has manual and automatic tool feeding functions. The tool feeding speed is adjusted by frequency converter. The tool feeding speed can be adjusted as required. 2. Chamfer angle: 45 degree chamfer angle can be customized. Chamfer range: 0 ~ 6mm 3. The rotating speed of the main cutter head is 2860 rpm, which is powerful and can be used to mount 6 blades. The blade model is 1203 (12.7 long × Length 12.7 × Thickness 3.2) 4. Suitable for batch processing of large workpieces, molds, mold base chamfering, sheet metal processing, machine and equipment manufacturing, etc., the chamfering finish of workpieces is good, forming once, without secondary grinding 5. Cold cutting with milling cutter can avoid the influence of ordinary flame cutting on materials. 5. This machine has the advantages of simple operation, cost saving and high working efficiency. It is the first choice necessary for hardware mold, machining and mold embryo processing plants. 6. It is widely used in mold, mold base, metal processing, steel structure, shipbuilding, power plant, petroleum, chemical and other production and processing industries.

National Advisory Hotline:

138-2575-1784Product features:

1. The machine has manual and automatic tool feeding functions. The tool feeding speed is adjusted by frequency converter. The tool feeding speed can be adjusted as required.

2. Chamfer angle: 45 degree chamfer angle can be customized. Chamfer range: 0 ~ 6mm

3. The rotating speed of the main cutter head is 2860 rpm, which is powerful and can be used to mount 6 blades. The blade model is 1203 (12.7 long × Length 12.7 × Thickness 3.2)

4. Suitable for batch processing of large workpieces, molds, mold base chamfering, sheet metal processing, machine and equipment manufacturing, etc., the chamfering finish of workpieces is good, forming once, without secondary grinding

5. Cold cutting with milling cutter can avoid the influence of ordinary flame cutting on materials.

5. This machine has the advantages of simple operation, cost saving and high working efficiency. It is the first choice necessary for hardware mold, machining and mold embryo processing plants.

6. It is widely used in mold, mold base, metal processing, steel structure, shipbuilding, power plant, petroleum, chemical and other production and processing industries.

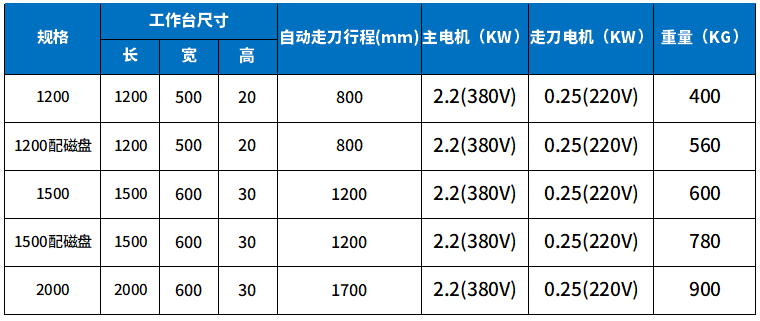

TW-900S high-speed linear chamfering machine

TW-900R curve chamfering machine

TW-900 high-speed compound chamfering machine

TW-900H high-speed compound adjustable chamfering machine

TW-900E high-speed slide rail chamfering machine

TW-900D high-speed compound slide rail chamfering machine

TW-140 portable linear chamfering machine

TW-300 side milling cutter chamfering machine

TW-400/500 plane cutter head/grinding wheel chamfering machine

开云(中国)